Over the past 25 years, the National Institute of Standards and Technology (NIST) has developed, augmented and improved an important computational tool for fire investigators – the Fire Dynamics Simulator (FDS) code.

FDS is a flow, heat, and chemistry modeling application that is utilizes Computational Fluid Dynamics (CFD) to model fires and other flows that are important to fire safety engineers and fire investigators. While other commercial CFD programs exist, their cost to license and their computational cost (hours of runtime) tend to make them inaccessible for small enterprises, including many fire investigation firms.

Fortuitously, FDS offered breakthroughs on several fronts that helped bring the power of CFD modeling to smaller practitioners. (Recently, a user-friendly, front-end package was developed by Thunderhead Engineering http://www.thunderheadeng.com/ and can be licensed for a reasonable annual fee.) Because the underlying code was developed by the U.S. Government, it is downloadable and usable by the general public with no license fees. Secondly, the program can be run on Windows-based desktop and laptop computers, so there is no need to purchase expensive hardware. Perhaps most importantly, the program uses a computational simplification called “Large Eddy Simulation” (LES) to enhance the speed at which complex flows can be solved numerically.

While LES does employ a computational shortcut (where only large eddies are directly solved and the dissipative energy generation of the small eddies is modeled as a byproduct of the large eddies) as compared to CFD programs that utilize Direct Numerical Simulation (where all the equations are solved for all sizes of turbulent eddies), the LES technique nevertheless produces fully-validated results for many fire problems.

The video posted below is a FDS simulation of a gasoline leak under a car inside a garage. The model incorporates a source of heptane vapor being released from a square “puddle” under the vehicle’s engine compartment. Contours of heptane concentration versus time are shown in the simulation output – red is flammable, orange is possibly flammable, yellow is probably not flammable, and green/blue/purple are not flammable. It is noteworthy that the red contours do cover the entire floor surface, but because gasoline vapors are heavier than air, the flammable concentrations don’t rise up very high above the floor level.

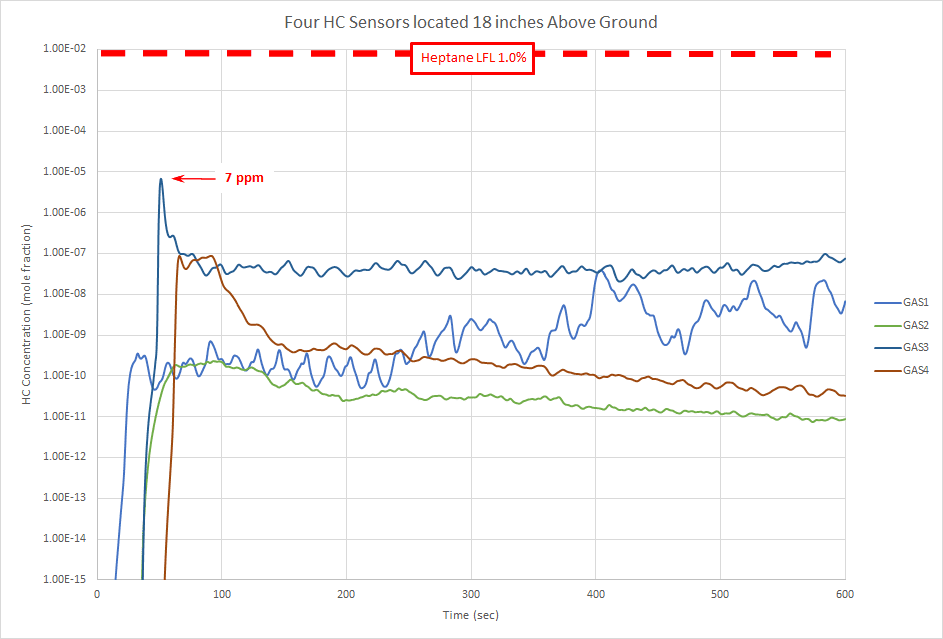

Also posted below is a plot of hydrocarbon concentration measured by four sensors located in the corners of the garage, at an elevation of approximately 18 inches above the floor. The Consumer Product Safety Commission performed tests of the safety of water heaters in garages approximately 25 years ago and found that flash fires involving gasoline spills ignited by the pilot flame of a water heater were largely preventable if the water heaters were installed on pedestals so that the flames were at least 18 inches up in the air.

The plot below validates the CPSC’s finding. The maximum concentration at the four sensors during the 10 minute duration of the simulation run was 7 parts per million, by volume. This is more than 99.9% smaller (three orders of magnitude smaller) than the Lower Flammable Limit of heptane (1.0 percent by volume). In other words, the mixture is too lean to produce a deflagration at the elevation of the water heater’s burner, if the heater is installed on pedestal, in adherence with the requirements of the National Fuel Gas Code.

The purpose of “Investigation Anecdotes” is to inform our readers about the intriguing field of engineering investigations. We hope you are instructed by this content, and we encourage you to contact us if you seek additional information.